For modern off grid farmers and rural business owners, energy is not merely a utility; it is the heartbeat of production. Whether you are running poultry ventilation fans in Nigeria or irrigation pumps in rural Australia, reliance on diesel generators is a financial hemorrhage that eats into profit margins. The transition to a dedicated energy storage solution is no longer just an environmental choice; it is a strategic asset acquisition. This guide details how to leverage professional grade home battery power storage to close the loop on energy costs, ensure 24/7 automation, and transform your power supply from a recurring expense into a depreciating asset.

Asset Based Energy System

Many agricultural operators hesitate to adopt solar storage due to the upfront capital expenditure (CAPEX). However, this hesitation often stems from viewing electricity as an operating expense (OPEX) rather than an infrastructure asset. When you rely on diesel generators, you are renting your power. You pay for fuel, transport, filter changes, and engine overhauls forever. The money leaves your account and never returns value. By contrast, installing a robust off grid system converts that monthly rent into an owned asset that adds value to the property and reduces marginal production costs to near zero after the payback period.

Consider the five years cost trajectory of a typical 20kW load farm operation running 12 hours a day.

| Cost Component | Diesel Generator Scenario (5 Years) | Solar + Battery Storage Scenario (5 Years) |

| Initial Hardware Cost | $15,000 (Generator + Switchgear) | $45,000 (Inverters, PV, Batteries) |

| Fuel Costs ($1.1/L) | $128,000 (Escalating at 5%/year) | $0 |

| Maintenance/Parts | $12,000 (Oil, Filters, Labor) | $2,000 (Cleaning, Inspection) |

| Replacement/Overhaul | $5,000 (Engine rebuild at Year 4) | $0 (LiFePO4 lifespan > 10 years) |

| Total 5-Year Cost | $160,000 | $47,000 |

| Asset Value at Year 5 | < $4,000 (Depreciated machinery) | > $20,000 (System residual value) |

Data Source: Internal industry analysis based on 2024 average global diesel prices and current Tier 1 LiFePO4 battery pricing.

The math is unambiguous. The home battery power storage system pays for itself, typically within 24 to 36 months, depending on local fuel prices. After this break even point, your farm operates on free energy, giving you a massive competitive advantage over neighbors still buying fuel.

Matching System Capacity to Production Loads

A common failure mode in off grid projects is undersizing the inverter capacity, not for the running load, but for the startup surges of inductive loads like water pumps and compressors. To avoid this, we do not simply guess the size; we use a tiered load management strategy. You must categorize your farm equipment into two distinct groups:

Level 1: Critical Loads (Must Run 24/7)

These are the devices where power failure equals financial loss. Examples include incubators, vaccine fridges, cold storage compressors, and security systems. Your battery bank must be sized to support these for at least 24 hours of autonomy without solar input.

Level 2: Deferrable Loads (Flexible Timing)

These include irrigation pumps, feed mills, and general lighting. These should be scheduled to run only during peak sun hours (10:00 AM to 3:00 PM) when the solar array is producing excess power.

The Modular Deployment Path

Instead of overspending on day one, adopt a modular inverter architecture. Start with a core system that covers all Level 1 loads. Ensure your chosen inverter allows for parallel connection (stacking). This allows you to add more power modules and battery capacity later as your farm expands, without making your initial investment obsolete. This approach reduces initial financial pressure while keeping the pathway to full automation open.

LiFePO4 Performance in Harsh Environments

Farms are hostile environments for electronics. Dust, high humidity, ammonia (in poultry sheds), and extreme temperature fluctuations are the enemies of power electronics. A standard residential unit designed for a climate controlled garage will fail in an external pump house.

Environmental Adaptation

To ensure longevity, the installation must adhere to strict environmental standards. We recommend using equipment with a minimum rating of IP54, which protects against dust ingress and splashing water. Furthermore, the installation site should be raised at least 20cm off the ground to prevent flood damage and facilitate airflow.

The Chemistry Advantage

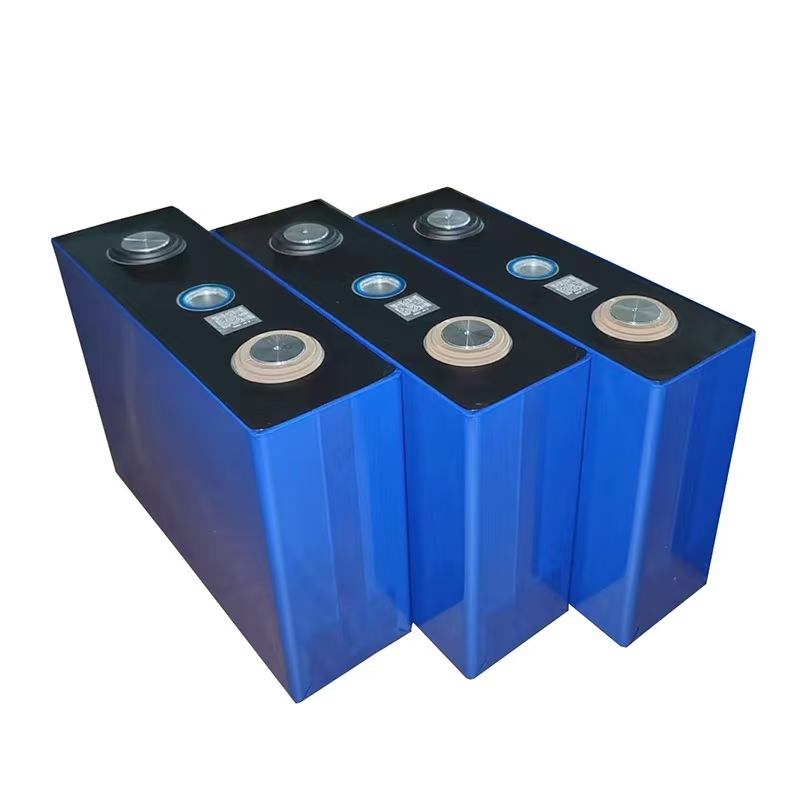

The shift from Lead Acid to Lithium Iron Phosphate (LiFePO4) is non negotiable for productive use. In an agricultural setting, batteries are cycled deeply every single night. Lead acid batteries typically fail after 500-800 deep cycles. Modern LiFePO4 batteries offer 6,000+ cycles at 80% Depth of Discharge (DOD). In practical terms, this means a LiFePO4 system installed today will likely still be operational in 2040. For a farm manager, this reliability eliminates the range anxiety of wondering if the batteries will survive through a cloudy week. It transforms the battery bank from a consumable item into permanent infrastructure.

Standardized Delivery

A major barrier to entry for rural farms is the complexity of installation and the fear of being left with a system no local electrician can fix. To mitigate this, the industry has moved toward pre assembled solutions. Modern off grid systems should not be a puzzle of wires delivered in loose boxes. The best practice involves pre assembling the inverter, busbars, and protection devices (breakers/fuses) into a unified cabinet at the factory. This pre wired approach reduces on site labor by 80%. You do not need to be an electrical engineer to maintain these systems. With integrated WiFi or GPRS monitoring modules, the system status can be viewed remotely by the manufacturer's support team. If a fault occurs, for example, if a specific battery module is underperforming, technicians can diagnose the issue over the cloud before a mechanic ever visits the site. This capability reduces the Mean Time to Repair (MTTR) from weeks to hours, ensuring your farm's production never skips a beat.

Conclusion

By treating your power supply as a vital business asset, sizing it correctly for your critical loads, and utilizing robust LiFePO4 technology, you secure your farm's future against rising fuel costs and grid unreliability.

✉️Email: exportdept@snadi.com.cn

Website:

☎️WhatsApp / WeChat: +86 18039293535

FAQ

1. How does integrating a battery storage system specifically improve the efficiency of automated irrigation systems?

Battery storage systems ensure that automated irrigation can run during optimal times, such as early morning or late evening, without relying on expensive peak hour grid electricity. By storing solar energy collected during the day, the system provides a steady power source for water pumps and sensors, ensuring that crops receive consistent hydration even during cloudy weather or power fluctuations.

2. Can a residential grade battery storage system handle the power demands of automation in a large scale farm?

While individual residential units are designed for specific loads, these systems are often modular and can be scaled to meet the growing demands of a farm. For automation, they are exceptionally effective at powering control units, smart sensors, and automated feeding machines. For larger equipment, multiple units can be integrated to create a robust energy network that reduces overall operational costs and provides a reliable backup for critical automated processes.

3. What happens to my farm automation data and sensors during a sudden power grid failure?

One of the primary benefits of using a battery storage system is the provision of an uninterruptible power supply. If the main grid fails, the battery system immediately takes over, ensuring that your automation hub remains active. This prevents any loss of data from environmental sensors and ensures that automated systems like climate control in greenhouses or ventilation in livestock barns continue to function without interruption.

4. Is it difficult to integrate battery storage with existing traditional farming equipment and automated tools?

Most modern battery storage systems are designed with high compatibility and can be retrofitted into existing farm infrastructures. They typically interface with smart energy management software that allows farmers to monitor and prioritize power distribution to specific automated tools. This seamless integration allows for a gradual transition toward full farm automation without needing to replace all existing electrical setups at once.

5. How does automating a farm with battery storage contribute to long term financial sustainability?

Automating with battery storage reduces the long-term overhead by minimizing electricity bills and reducing the need for manual labor in routine tasks. By utilizing self generated solar energy, farmers protect themselves against rising utility costs. Additionally, the increased precision of automated systems, supported by reliable battery power, leads to less waste of water and nutrients, further improving the overall profitability and sustainability of the agricultural business.

FAQ

The energy consumption standards for household appliances are usually regulated by relevant national departments, and different products have different energy efficiency level standards. Consumers can choose energy-saving products based on their energy efficiency levels.

What are the precautions for repairing and maintaining household appliances?

What is the service life of household appliances?

What issues should be noted when purchasing household appliances?

What issues should be noted when purchasing household appliances?

How long is the warranty period for household appliances?

How to use household appliances for energy-saving purposes?