The global agricultural sector faces a pivotal transition in 2026 as diesel costs remain volatile and the demand for sustainable food chains intensifies. For large scale farming operations, energy is not just a utility but a critical production input. Modern agribusinesses rely on heavy machinery, automated irrigation, and climate controlled storage, all of which demand a stable and high capacity electrical supply. This requirement makes three phase solar power the definitive standard for those seeking true energy autonomy and operational resilience in remote locations.

Precision Load Audits for Inductive Farm Loads

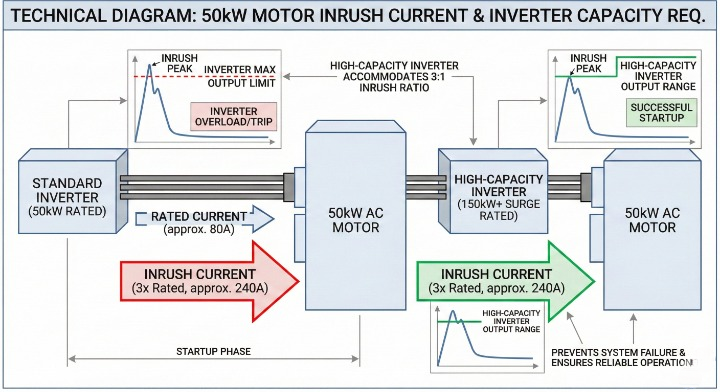

The first step in moving away from diesel dependence involves a rigorous assessment of the farm production boundary. Unlike residential setups, agricultural environments are dominated by inductive loads such as high power motors, crushers, and irrigation pumps. These devices require an immense amount of energy during the startup phase, known as inrush current. Failing to account for this can lead to system shutdowns or premature equipment failure.

When engineering a robust system, the peak power rating must be calculated with a three to one margin relative to the nominal power of the motors. For instance, a 50kW irrigation pump might require nearly 150kW of instantaneous surge capacity. High performance low frequency inverters, such as the SNADI/SNAT Solar TP or NKG series using IGBT technology, are specifically designed to handle these surges without compromising the life of the inverter. These systems provide a complete isolation of the output power supply, ensuring that the harmonic distortion remains below 3% for linear loads and below 5% for non linear loads.

Proper phase balancing is another engineering necessity. In a typical farm, single phase domestic loads for housing or offices often coexist with three phase production loads. Unbalanced phases can lead to excessive neutral line current and thermal losses. Utilizing advanced independent phase control technology allows for a reduction in reactive power waste by up to 5%, directly lowering the total cost of ownership by preventing heat damage to the wiring infrastructure.

Achieving Zero Downtime in Remote Scenarios

In an off grid environment, electricity equals productivity. A power failure at a dairy farm or a cold storage facility can result in catastrophic financial losses within hours. Therefore, the architecture must focus on zero downtime through the integration of Energy Storage Systems (ESS) and smart energy management.

A DC Coupled solution is often superior for agricultural productivity. By converting photovoltaic energy directly into storage or kinetic power for pumps, the system avoids the losses associated with secondary inversion. This integration can improve overall efficiency by as much as 12% compared to traditional AC coupled setups. Furthermore, the use of Lithium Iron Phosphate (LiFePO4) battery technology, like the BL series, provides a service life of up to 6000 cycles at 25°C, ensuring the storage component lasts for a decade or more.

Frequency stabilization is a subtle yet vital factor. Automated milking machines and precision temperature controllers are highly sensitive to frequency drifts. SNADI/SNAT Solar three phase inverters utilize high frequency sampling to rectify frequency deviations in real time, maintaining a steady 50Hz or 60Hz output within a 0.5% margin even when the battery is the sole source. This prevents microcontrollers from crashing and ensures that the automation software governing the farm remains operational.

Comparing Operational Economics

To understand the value of three phase solar power, one must look beyond the initial capital expenditure and evaluate the ten year earnings curve. Diesel generators are a cycle of constant expense, involving fuel procurement, logistics, and frequent mechanical maintenance.

| Dimension | Traditional Diesel Generator (200kVA) | Three Phase Solar Power System (200kVA) |

| Five Year Operating Cost | Extremely High (Fuel + Maintenance) | Near Zero (Basic Cleaning Only) |

| Equipment Lifespan | Three to Five Years (High Load Run) | Ten to Fifteen Years |

| Return on Investment | None (Pure Expense) | 2.5 to 4 Years (Location Dependent) |

| Environmental Impact | High Emissions and Noise | Zero Emissions and Silent Operation |

The financial logic is clear: the transition to a solar based three phase system converts a perpetual liability into a tangible asset. Systems like the NKG series with built in MPPT controllers achieve conversion efficiencies of over 99%, maximizing every hour of sunlight into usable energy. This level of performance translates to roughly fifteen additional days of free electricity annually compared to lower grade equipment.

Standardized Installation and Modular Scaling

One of the primary fears for farm owners is the complexity of high voltage installation. To mitigate this, modern solutions move toward a pre integrated, modular approach. Integrated PV energy storage cabinets, such as the NKG-S215A100, combine the BMS, PCS, and EMS into a single IP55 rated enclosure. This reduces onsite installation time by approximately 60%, as the complex internal wiring is completed and tested in a factory environment before shipping.

This modularity also allows for a staged investment strategy. A farm owner can begin with a core 30kW system to power essential irrigation and scale up to a 150kW or 200kW system as the operation expands. Parallel stacking technology allows for as many as sixteen units to work in tandem, providing a flexible expansion path that saves both time and cost.

Managing Environmental Extremes and Unpredictable Weather

Farm equipment must be resilient against the elements. Whether it is a dusty feed processing room or a damp pump house, the electrical core must be protected. High grade systems feature detachable dust covers and robust cooling designs, often using temperature controlled intelligent exhaust fans to maintain optimal operating temperatures.

Furthermore, the Energy Management System (EMS) plays a crucial role during periods of heavy cloud cover. When a sudden drop in solar harvest occurs, the EMS dynamically prioritizes production loads. It might temporarily cut power to non-essential areas, like staff quarters or water heaters, to ensure the main irrigation pumps continue to run. This intelligent load shedding is what separates a professional agricultural system from a standard residential one.

Conclusion

The engineering of a high ROI three phase system is a strategic move toward long term viability. By focusing on high surge capacity, precision phase balancing, and modular energy storage, farm owners can eliminate the risks associated with fuel shortages and grid instability. As we look toward the remainder of 2026 and beyond, the adoption of three phase solar power stands as the most effective method for farmers to reclaim control over their energy destiny and ensure a sustainable, profitable future.

✉️Email: exportdept@snadi.com.cn

Website:

☎️WhatsApp / WeChat: +86 1803929353

FAQ

Q1. Why is three phase solar power more cost effective than diesel generators for farms?

Diesel generators create a continuous cycle of fuel procurement, logistics, and high maintenance. Three phase solar systems eliminate these recurring expenses and offer a return on investment within 2.5 to 4 years. By switching to solar, farmers convert a perpetual liability into a tangible asset that provides silent and emission-free energy for over a decade.

Q2. How do these systems handle the high startup power needed for irrigation pumps?

Agricultural loads like pumps and crushers require massive inrush currents during startup. The SNAT Solar systems use low frequency inverters with IGBT technology designed to provide surge capacities up to three times the nominal load. This ensures that a 50kW pump can start reliably without causing system shutdowns or damaging sensitive electrical components.

Q3. What role does phase balancing play in agricultural energy efficiency?

Farms often run single phase office loads alongside three phase machinery, which can cause unbalanced phases and thermal losses. Advanced phase control technology manages these loads independently to reduce reactive power waste by up to 5 percent. This precision protects wiring infrastructure from heat damage and lowers the total cost of ownership.

Q4. Can the system maintain operations during periods of heavy cloud cover?

The integrated energy management system is designed for reliability. During low solar harvest, the software dynamically prioritizes essential production loads like irrigation and cold storage. It can perform intelligent load shedding by temporarily cutting power to non-essential areas like staff quarters to ensure that critical farming operations continue without interruption.

Q5. Is the installation and expansion process complex for large scale operations?

Modern solutions use a modular approach with pre-integrated energy storage cabinets that combine battery management and inverter systems. This reduces onsite installation time by roughly 60 percent. Additionally, parallel stacking technology allows farm owners to start with a smaller setup and expand up to 200kW or more as their operational needs grow.

FAQ

The energy consumption standards for household appliances are usually regulated by relevant national departments, and different products have different energy efficiency level standards. Consumers can choose energy-saving products based on their energy efficiency levels.

What are the precautions for repairing and maintaining household appliances?

What is the service life of household appliances?

What issues should be noted when purchasing household appliances?

What issues should be noted when purchasing household appliances?

How long is the warranty period for household appliances?

How to use household appliances for energy-saving purposes?