As of 2026, 580W solar panels have become a standard for large scale residential and commercial off grid installations due to their high energy density and efficiency. However, the sheer power output of a single 580W panel requires precise calculation to avoid equipment failure and maximize energy harvest. This technical overview explores the exact mathematical requirements and hardware specifications needed to support these powerful modules in modern energy storage systems.

Recommended Controller Specs

For a single 580W solar panel, the most effective choice is a 60A MPPT controller if you are using a 24V battery bank, or a 30A to 40A MPPT controller for a 48V battery bank. Using a 12V battery system with such a high wattage panel is generally discouraged because the resulting current is extremely high, leading to significant thermal loss and requiring oversized, expensive cabling. The following table summarizes the required current ratings based on common battery bank voltages used in off grid scenarios.

| Battery System Voltage | Calculated Current (580W / V) | Recommended Controller Rating (Including 25% Margin) | Efficiency Level |

| 12V System | 48.33 Amps | 60A to 80A | Very Low |

| 24V System | 24.16 Amps | 40A to 60A | High |

| 48V System | 12.08 Amps | 20A to 30A | Very High |

How to Calculate the Right Size Step by Step

To determine the exact size for your specific installation, you must look beyond the simple wattage. Environmental factors and electrical safety codes like the National Electrical Code (NEC) require specific buffers.

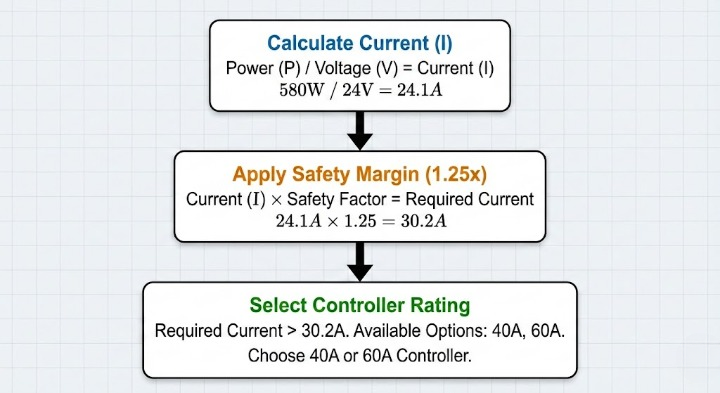

Step 1: Amperage Calculation (The Formula)

The base calculation uses the standard power equation for current where I represents the current in Amps, P is the panel wattage, and V is the charging voltage of the battery bank.

For a 580W panel charging a 24V system, the nominal current is 580 / 24 = 24.16A. It is important to remember that battery voltages fluctuate during the charging cycle. A 24V lithium battery might actually be charging at 28.8V, which would lower the current, but we always calculate based on the lowest nominal voltage to ensure the controller can handle the maximum possible amperage.

Step 2: The 1.25 Safety Factor

Industry standards require a safety margin of at least 25 percent. This accounts for a phenomenon known as the cloud edge effect, where sunlight reflecting off the edges of clouds can momentarily boost a panel's output beyond its rated STC (Standard Test Conditions) wattage.

24.16A✖️1.25 = 30.2A

In this scenario, a 30A controller would be operating at its absolute limit. Therefore, upgrading to a 40A or 60A unit provides a healthy buffer and prevents the hardware from overheating during peak summer hours.

Step 3: Voltage Compatibility (Voc vs Max Input)

The 580W panels typically utilized in 2026 feature an Open Circuit Voltage (Voc) between 45V and 55V. When choosing your hardware, you must ensure the maximum input voltage rating of the controller exceeds the Voc of the panel, adjusted for cold weather. In freezing temperatures, the voltage of a solar panel increases. If your panel has a Voc of 50V and you use a controller only rated for 60V, a cold, sunny morning could easily destroy the internal circuitry.

Why MPPT is Non Negotiable for 580W Panels

For panels exceeding 200W, a Pulse Width Modulation (PWM) controller is no longer a viable option. PWM controllers work by pulling the panel voltage down to match the battery voltage, which results in massive power wastage. For a 580W panel with a peak power voltage (Vmp) of 42V charging a 12V battery, a PWM controller would discard nearly 70 percent of the potential energy.

An Maximum Power Point Tracking (MPPT) controller acts as an intelligent DC to DC converter. It takes the high voltage, low current output from the panel and transforms it into the lower voltage, higher current needed by the battery.

Industry Efficiency Data

According to the 2025 Annual Solar Components Report by BloombergNEF, MPPT technology has achieved a conversion efficiency average of 98.5 percent across tier one manufacturers. The data suggests that in northern climates or during winter months, MPPT controllers harvest up to 30 percent more energy than PWM alternatives. This is because panels operate at higher voltages in cold weather, and only MPPT can utilize that extra voltage to increase charging current.

| Feature | PWM Controller | MPPT Controller |

| Efficiency | 65% to 75% | 94% to 99% |

| Best Application | Small 12V systems (<200W) | High power modules (>200W) |

| Cost | Lower initial cost | Higher but pays back in energy |

| Performance in Shade | Poor | Excellent |

Overpaneling with a 580W Setup

Many modern controllers allow for a practice called overpaneling. This involves connecting more solar wattage than the controller is rated to output. For example, you might connect a 580W panel to a controller rated for 400W output.

The controller will simply limit the output to its maximum rating, which is known as current limiting. The benefit is that during cloudy days or early mornings, you will harvest more power than a smaller panel would provide. However, you must never exceed the maximum input voltage (Voc) of the controller. Exceeding the voltage is fatal for the device, while exceeding the wattage (within manufacturer limits) is often a strategic design choice to improve low light performance.

Common Pitfalls to Avoid

Using Thin Wiring

A 580W panel produces substantial current. If you use standard thin gauge wire over long distances, you will experience a significant voltage drop. This heat generation is not only inefficient but can be a fire hazard. Always use at least 10AWG or 8AWG PV wire for the run between the panel and the controller.

Ignoring Temperature Coefficients

As mentioned previously, voltage rises as temperature falls. Professionals use the temperature coefficient listed on the panel datasheet to calculate the absolute maximum Voc at the lowest expected temperature for the site. Neglecting this is the leading cause of controller failure in winter.

Summary Checklist for Buying

Confirm the Voc of your panel is at least 20 percent lower than the controller's max input voltage.

Match your battery bank voltage to the controller's capabilities.

Select MPPT to ensure you are not wasting 30 percent or more of your 580W investment.

Ensure the controller supports your specific battery chemistry, such as LiFePO4 or Lead Acid.

Conclusion

When you are investing in a high performance 580W solar panel, the charge controller is the most important link in your off grid power chain. For a standard 24V ESS setup, a 60A MPPT controller provides the best balance of safety, future expansion capability, and thermal management. For 48V systems, which are increasingly common in 2026 for high capacity home storage, a 30A or 40A MPPT controller is perfectly sufficient and highly efficient.

Avoid the temptation to save money by purchasing a PWM controller or a unit with no safety margin. The efficiency gains of an appropriately sized MPPT controller will typically pay for the price difference within the first year of operation through increased energy production.

✉️Email: exportdept@snadi.com.cn

Website:

FAQ

MPPT controllers are essential for high power modules like the 580W panel because they act as efficient converters. Unlike PWM controllers that waste excess voltage by pulling it down to battery levels, MPPT technology optimizes power harvest by tracking the maximum power point. This can increase energy production by up to thirty percent in colder climates where panel voltage is naturally higher.

Q2: Why do experts recommend a twenty five percent safety margin for sizing?

Q3: Is it efficient to use a 12V battery system with a 580W solar panel?

Q4: How does temperature affect the choice of a charge controller for a 580W panel?