The agricultural landscape in 2026 has shifted toward a model where the home and the production facility are inseparable nodes of energy consumption. For modern farm owners, securing reliable backup battery power for home and operation is no longer a luxury but a fundamental strategy for economic resilience. As global energy storage capacity additions are projected to grow by 23 percent in 2025 according to BloombergNEF, the focus for top tier providers has moved from simply selling hardware to delivering precise energy audits that safeguard the harvest.

Why Calculation First Beats Product First

Traditional sales approaches often push standardized 5kWh modules without understanding the underlying agricultural logic. In 2026, the industry has matured beyond these generic offerings. A professional engineer does not start by discussing lithium iron phosphate battery cycle life: they start with an energy audit.

The goal is to identify the minimum running base for irrigation systems and cold storage during non-sunlight hours. By focusing on this logic, providers can reduce ineffective hardware investment by up to 30 percent. This approach prioritizes substituting high maintenance diesel generators with quiet, autonomous storage that eliminates the volatile costs of fuel procurement and transport.

The HOW of Sizing: 3 Steps to Precision Engineering

Farms often feel the weight of high system costs because suppliers size equipment based on peak demand rather than operational logic. Achieving a cost effective setup requires a three step engineering process.

Step 1: Conduct a Critical Load Audit

Agricultural loads must be classified into lifeline loads and delayed loads. Lifeline loads include brooding temperature controls, automatic feeders, and essential security systems. Delayed loads, such as non-critical irrigation or domestic hot water, can be timed to coincide with peak solar production. By recording a 24 hour load curve and focusing on the high starting currents of inductive loads like pump motors, engineers can optimize the system to avoid over-sizing the inverter, effectively compressing initial storage costs by 20 percent.

Step 2: Defining Autonomy Days Without Overspending

The year 2026 marks a departure from seeking infinite redundancy. Modern off-grid logic seeks the optimal balance of autonomy. By analyzing local meteorological data to determine the probability of consecutive rainy days, a standard of 1.2 to 1.5 days of autonomy is typically recommended for most agricultural sites. Blindly pursuing a 3 day reserve often leads to a diminishing return on investment where the extra battery capacity remains unused for 95 percent of the year.

Step 3: Calculating Total Capacity

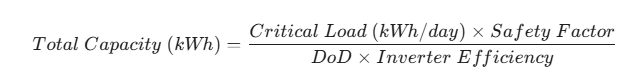

To arrive at the final specification, the following precision formula is applied:

This calculation highlights the efficiency of LiFePO4 technology, which allows for a 90 percent depth of discharge compared to the 50 percent limitation of legacy lead acid systems. This technical edge directly lowers the levelized cost of energy across the life of the farm.

Typical Sizing Scenarios for Modern Farms

Based on the latest Wood Mackenzie energy storage monitor reports, agricultural implementation generally falls into three distinct profiles.

| Scenario | Recommended Capacity (kWh) | Primary Goal | 10 Year Projected ROI |

| Basic Family Farm | 15kWh to 30kWh | Covers night lighting, home appliances, and surveillance. | Replaces 85 percent of diesel fuel purchases. |

| Production Ag Center | 60kWh to 120kWh | Drives 5HP pumps, ventilation, and small cold storage. | Prevents crop loss valued at 20,000 USD or more. |

| Full Off-Grid Ranch | 200kWh plus | Full autonomy for machinery charging and heavy irrigation. | Zero energy bills and enhanced green brand premium. |

Technical Implementation: Ensuring Long Term Reliability

Reliability in a farm environment depends on how the system reduces operating expenses (OPEX) over a decade of service.

DC Coupling in Off-Grid Setup

For new agricultural installations, DC coupling is the preferred architecture. This method allows solar power to charge batteries directly without redundant conversions. In practice, this improves charging efficiency by 5 to 8 percent compared to AC coupled alternatives. For a farm with high daytime loads, these marginal gains accumulate into thousands of kilowatt hours saved over the system lifespan.

Modular Scalability: The Pay As You Grow Model

Modern lithium systems allow for vertical or stacked expansion. This means a farm owner does not need to invest 100,000 USD on day one. A strategic deployment might begin by securing the core breeding area power, with additional battery modules added in subsequent years as operational cash flow allows. This reduces initial capital pressure while maintaining the flexibility to scale as production expands.

The Financial Blueprint: ROI Analysis for Cost Sensitive Owners

The most critical question for any owner remains the timeline for capital recovery. In the current 2026 economic environment, the financial profile of a high quality storage system is defined by its lifecycle costs.

Initial CAPEX: The cost of hardware and installation.

Reduced OPEX: The sum of saved electricity bills, avoided fuel costs, and the absence of generator maintenance labor.

In many regions, off-grid agricultural systems now achieve a full return on investment within 4.5 to 6 years. Given that modern lithium iron phosphate systems are engineered for a 10 to 15 year service life, the subsequent decade provides essentially free energy, providing a massive competitive advantage in a market where production costs continue to rise.

Conclusion

Choosing the right backup battery power for home and farm operations is a strategic move toward long term stability. In 2026, the best systems are defined not by their peak wattage, but by their ability to integrate seamlessly with the specific rhythms of agricultural life. By prioritizing rigorous energy audits and modular technical paths, farm owners can transform energy from a variable cost into a fixed, reliable asset.

✉️Email: exportdept@snadi.com.cn

Website:

FAQ

A backup battery system provides a continuous power supply for essential farm infrastructure such as irrigation pumps, livestock feeding systems, and ventilation. By preventing downtime during grid outages, it protects against the loss of sensitive crops and animals, ensuring the farm remains profitable and operational under all conditions.

Q2: How does solar battery storage reduce farm operating costs?

Q3: Can a home battery system power large agricultural equipment?

Q4: What are the environmental benefits of using backup batteries on a farm?

Q5: Is a backup battery system reliable in extreme weather conditions?